Main achievements:

- The fundamental basis of vacuum pyro-selection of complex mineral and man-made raw materials have been created;

- The fundamental basis of vacuum distillation refining of metals and separation of alloys have been created;

- The vacuum process of refining rough tin at the Novosibirsk Tin Plant was developed and introduced.

- The vacuum thermal technology and equipment for the processing of mercury concentrates at the Khaidarkan mercury plant (Kirghizia) was put into commercial operation;

- Ecologically safe technologies have been developed for dearsenation stubborn gold-, arsenic-containing raw materials and demercurization of mineral and man-made materials that have been tested on a pilot scale in the vibro-vacuum installations of a continuous operation principle;

- A pilot production for refining rough selenium has been established at the experimental metallurgical production of “IMOB” JSC.

- “Kazakhmys Progress” LLP has introduced the technology of refining rough selenium by vacuum distillation method.

Technologies offered for implementation:

- Technology for producing titanium dioxide from ilmenite concentrate from the Obukhovskoye deposit;

- Advanced vacuum distillation technology for refining selenium;

- Environmentally friendly vacuum technology and continuously operating equipment for the demercurization of used mercury-filled instruments and measurements;

- Ecologically safe technology for dearsenation of refractory gold-bearing raw materials

Basic research directions:

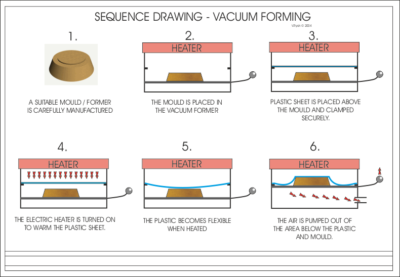

- The study of thermodynamic and kinetic regularities of evaporation processes, the thermal decomposition of metal sulfides and condensing in a vacuum;

- Development of a vacuum-thermal technology and equipment for processing of polymetallic mineral and man-made raw materials from non-ferrous metallurgy;

- Creation of vacuum distillation methods and equipment for refining of non-ferrous metals.

Laboratory staff:

The main structure of the research group consists of 6 people: 1 doctor of technical Sciences, doctor of physical and mathematical Sciences, Professor, 3 candidates of technical Sciences.

The contact person:

- Head Laboratory of vacuum processes: Nitsenko A.V.

- Work phone: 8 (727) 298-45-36, 8 (727) 298-45-37

- E-mail: a.nitsenko@imio.kz , nitc@inbox.ru